Integrated process & design for finishing

Each complex manufacturing process involves several phases, often accomplished combining different technologies. AM Solutions has developed in house the "Metal additive manufacturing cycle" by integrating the different production steps in a single, local and controlled area. Design for finishing is the answer of the complex challenge raised by additive to achieve superior surface characteristics, targets that can be reached only considering, implementing and controlling the whole process steps.

Optimal surface finishing results are strictly dependent on the preliminary design of integrated process strategies and technologies.

In fact, Design for finishing means acting on design and process parameters to ensure the required surface finishing and the compliance with the reference standard.

AM Solutions was born as a new company of the Rösler Group, global leader in the production of equipment and tailored solutions for surface treatment.

Metal 3D printing technologies have already become part of the production habits that many designers are dealing with: the concepts of topological optimization and design for additive are widely diffused. It is clear that additive manufacturing can bring important advantages in terms of weight reduction and freedom in geometries to the clients’ projects.

Although printing technologies are constantly evolving, the surface yield -especially in terms of dimensional consistency- is still quite far from being controlled in a such completely predictable way as it already happens with other production technologies.

Additive poses an additional challenge because of the variability of the surface treatment results, also depending on the process management and design choices.

AM Solutions combines Rösler Group’s deep knowledge of every aspect of surface treatment with an integrated industrial additive process. It consists in a complete and certified metal cycle including every phase and appearance, from design support, passing through industrialization and production, and ending with post-processing and finishing.

With Design for Finishing we intend all the activities that must be implemented, at the beginning of the project, on an Additive Manufacturing component to achieve a specific and often demanding level of surface finishing.

Design for Finishing includes:

- an evaluation of specific design practices that should take care of the manufacturability of the part but also minimize critical aspect in the post process and finishing steps,

- a definition of the process parameters in order to minimize the surface defects at a printing stage,

- a clear identification of the finishing strategy, often realized through different steps and technologies.

The industrial integrated additive process

DISCOVERY

The preliminary phase passes through the dialogue with the client, to fully understand his objectives and all the requirements of the project. In this way, the process can be adapted and carefully planned in all the subsequent needed activities.

DESIGN SUPPORT

An engineer- an expert at both additive optimization and Design for finishing- is assigned to every client and will work alongside the client’s designers to make the industrializable project compliant with the relevant requirements and regulations.

INDUSTRIALIZATION

Industrialization is the most critical phase. It is tailored depending on the technical and economic specifications of the project, and it defines the technologies to be used, the involvement of any external elements of the supply chain, the control and management plan of the different elements.

PRODUCTION & SUPPLY CHAIN MANAGEMENT

The production phase sees the coordinated management of resources and the cooperation of internal departments and vertical specialists to minimize the production time while maintaining the rigor borrowed from the highly regulated sectors.

POST PROCESSING

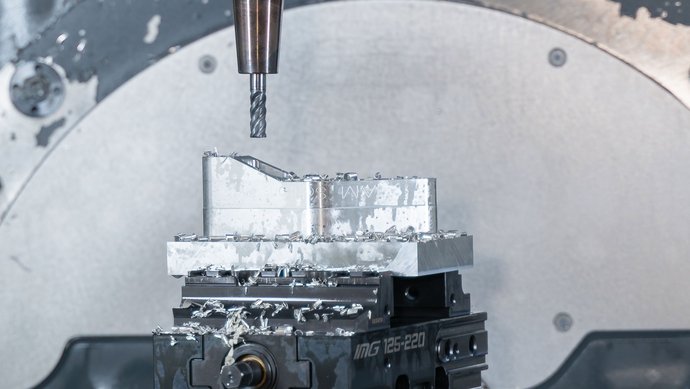

The post processing phase is often introductory to the finishing phase. A classic cycle begins with the dedusting, crucial especially in the presence of trabecular structures, and the detachment of the plate. The component can undergo heat treatment or be mechanically resumed to improve dimensional or shape accuracy/tolerances.

FINISHING

To obtain a specific surface finish, especially in the case of internal channels, it is necessary that the previous phases are carried out in perfect orchestration with each other. Drawing on the know-how and facilities of Rösler Group, AM Solution can access various types of surface treatments, literally covering every possible need.

TESTING

Additive manufacturing belongs to the special process class and requires accurate control over both the process and quality. Both mechanical and microstructural properties analysis- non-destructive and destructive testing- are performed to generate quality dossiers (COC) compliant with the reference certification.