All-round AM Solutions method

AM Solutions brings the value of industrial production in the Additive Manufacturing world with a more customer oriented approach and a method that can guarantee the matching with the requirements and the reliability of the production.

3D printing is probably the most disruptive modern revolution in manufacturing: it allows the creation of components with completely original shapes while maintaining the promise- in specific application areas- to bring obvious performance advantages.

3D printing and additive manufacturing are currently used as synonyms. Today, in the market, the second one assumes the value of technological refinement even if its main purpose remains the rapid prototyping. AM Solutions - born from the industrial experience of the Rösler Group - aims to transfer this kind of concepts and the industrialized approach and dynamics to the emerging technologies. In fact, its objective is to promote strictly controlled small and medium scale production processes, passing through a phase of rapid prototyping and finally satisfying the specific requests of the client base: industrialized level of the service.

HIGH LEVEL OF PROCESS CONTROL

Being rigorous in the design of any production step is key in all projects managed by AM Solutions.

- Control of raw materials

- Control of job preparation and printing processes

- Control of each process steps results and achievements

- Scheduled maintenance system

- Training and timely verification of human resources

- Downstream controls

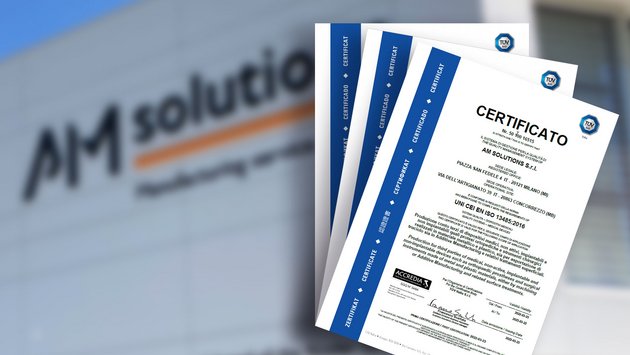

CERTIFICATIONS

Our certified working methods are applied to any of our projects irrespective of whether the project falls within a specific regulated environment:

- Design for finishing

- open model production

- post process, heat treatment and mechanical recovery

- functional surface finishing

They apply to any area in which the generation of a complete documentation and the taking of a responsibility are required. Achieving certifications is a natural step to prove that -even in case of specific industries -the AM Solutions method is ready to be adopted in order to get high quality and repeatable result.

Achieving certifications is a natural step to prove that -even in case of specific industries -the AM Solutions method is ready to be adopted in order to get high quality and repeatable result.

SUPPLY CHAIN CONTROL AND SUPPLIERS

Operating in a system open to the collaboration of vertical specialists brings enormous advantages compared to a completely internalized production, but exposes to critical issues regarding a suitable management of the relative risks. Each step of the production chain is suitable for the same level of process control reserved for all the internal working phases.

LOT TRACKING

Certifications require the traceability of every single batch arising from the production process. In fact, it is necessary having access to the whole history of a product production.

ANALYSIS AND TESTING

The steps before the final approval are certainly the most critical. In fact, a rigorous quality control is constant throughout the execution of the whole process.

QUALITY DOSSIER (COC)

Documentation is one of the most important keys to ensure, over time, a perfect adherence to both project specifications and reference legislation. The chance to replicate an identical production process and having same results is depending on the accuracy of the documentation.